Can customize templates for angled and rounded corners as well as large corner columns

Specifications:Customize according to the required size

Specifications:Customize according to the required size

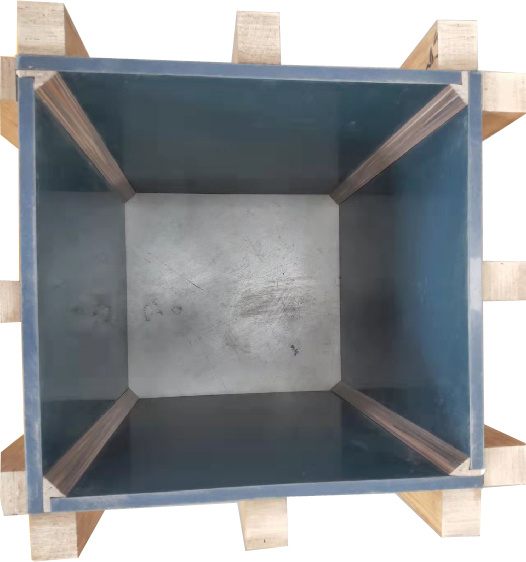

Scope:Construction of chamfered square columns

Scope:Construction of chamfered square columns

Number of uses:Can be reused more than 20 times

Number of uses:Can be reused more than 20 times

Phone/WeChat : +86 150 9292 9372

Chamfering customization: Currently, the workshop has rubber strips with rounded corners of 2cm and 5cm, as well as right angle strips. All can be processed and customized.

Customization of square columns: Even if the height of the widened square column does not exceed 1220cm, it can be used as a template with a clear water effect.

Attention: For widened square columns, due to limited equipment width, it is not possible to apply veneers, and only external nails with a height of less than 6 meters can be used. Widening square columns can also be connected to shear walls on both sides, or connected to upper and lower formwork (both of which may cause vertical and horizontal joint problems), but can be veneered with good water effect.

1. Square column templates can be produced to different sizes according to customer requirements. The template thickness can be selected from 15mm and 18mm. The wooden side can be selected from 40 * 50mm and 40 * 100mm specifications. The wooden side is made of LVL multi-layer board, which is cut into single boards through raw material rotation, dried, coated with glue, and assembled according to the grain pattern. It is then bonded by hot pressing.

2. High strength, high toughness, pressure resistance, no deformation, no cracking, and no gaps. Unlimited splicing of wooden blocks, the height of a single template can achieve a 6-meter appearance without splicing. Internal nail. The sheet material adopts a thickness of 0.3mm and is self-produced with a blue surface. After the veneer is completed, the product can achieve a clear water effect and bond firmly. Do not open the glue.

3. The actual thickness of the template is 14.5mm. The overall size error is within± About 1 mm. For the template docking point, there is a noticeable unevenness on the surface after pasting, and the production process is normal and does not affect its use. The benefits include good demolding effect and high construction efficiency. Save manpower. Reduce materials and costs. The turnover frequency can reach 10-15 times under normal use and maintenance (the intermediate use and parking time should not be too long).

Plastic covered wooden formwork Shape first and then apply plastic coating The surface of the template is smooth and flat without nail holes.

Plastic covered wooden formwork Shape first and then apply plastic coating The surface of the template is smooth and flat without nail holes.  Supporting templates easier Customize according to drawings or requirements in the factory Assembly type formwork on construction site.

Supporting templates easier Customize according to drawings or requirements in the factory Assembly type formwork on construction site.  Four meter template Four meter template splicing integrated wooden beam Cut the wooden beam according to the standard size and thickness.

Four meter template Four meter template splicing integrated wooden beam Cut the wooden beam according to the standard size and thickness. Square Column Special Template New square column technology creates specialized templates for square columns Dismantle the template and form it into shape.

Square Column Special Template New square column technology creates specialized templates for square columns Dismantle the template and form it into shape.