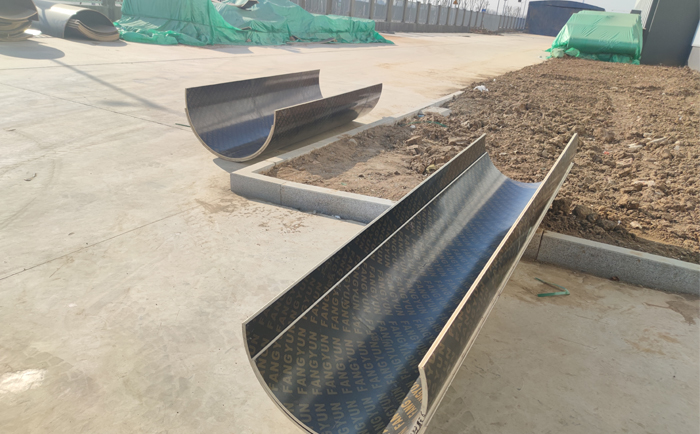

Special formwork for pouring concrete cylinders, all diameter sizes can be customized, with a plate thickness of 13/17/21mm, and the concave convex groove interface will not run during pouring.

Diameter:≥200mm Can be customized

Diameter:≥200mm Can be customized

Material:Birch and poplar wood

Material:Birch and poplar wood

Price:sale low-price $25 per square meter

Price:sale low-price $25 per square meter

Phone/WeChat : +86 150 9292 9372

Concrete cylindrical formwork solves the disadvantages of long production cycle and complex installation process of traditional steel formwork. It has the advantages of convenient and fast loading and unloading, and can be reused. Compared with similar products, it can save more than 60% of costs and is highly praised by various architectural design institutes and construction units. The most representative concave convex grooves and waistband like reinforcement components are tightly connected by joints to prevent grout leakage, making concrete demolding quick and aesthetically pleasing, while also providing stable reinforcement.

Lighter weight and better quality

Wooden building templates are made of high-quality birch and poplar wood, which is characterized by being lighter in weight than ordinary poplar wood, and having high strength and good toughness.

Faster installation speed

Due to the light weight of wooden building templates, they can be manually installed and disassembled in batches by 2-3 workers, without occupying tower crane equipment. A group of 2-3 workers can install 10-16 trees in eight hours.

The column is flat and smooth, well formed

It is made of plywood with large coverage, with few joints and seams. The birch and poplar wood material ensures the high strength and toughness of the template. The internal and external epoxy resin coating is not only smooth and waterproof, but also has a certain degree of breathability.

The concrete cylinder produced is not only smooth but also well formed, with excellent visual and tactile effects. The overall effect is superior to other similar products and belongs to the category of clear water formwork.

Can be cut arbitrarily Wooden circular templates can be cut to any size according to actual requirements.

Can be cut arbitrarily Wooden circular templates can be cut to any size according to actual requirements.  Easy to operate The circular template is lightweight and can be assembled by 2-3 people!

Easy to operate The circular template is lightweight and can be assembled by 2-3 people!  Solving the problem of beam passing Round wooden formwork can have any shape according to the construction of the project.

Solving the problem of beam passing Round wooden formwork can have any shape according to the construction of the project.  Demoulding without plastering Can be used multiple times up to 6-8 times easy to demold and operate.

Demoulding without plastering Can be used multiple times up to 6-8 times easy to demold and operate.