Current Location : Home > Product > Cylindrical Formwork > Cylindrical Wooden Formwork > Cylindrical wooden formwork

Current Location : Home > Product > Cylindrical Formwork > Cylindrical Wooden Formwork > Cylindrical wooden formwork

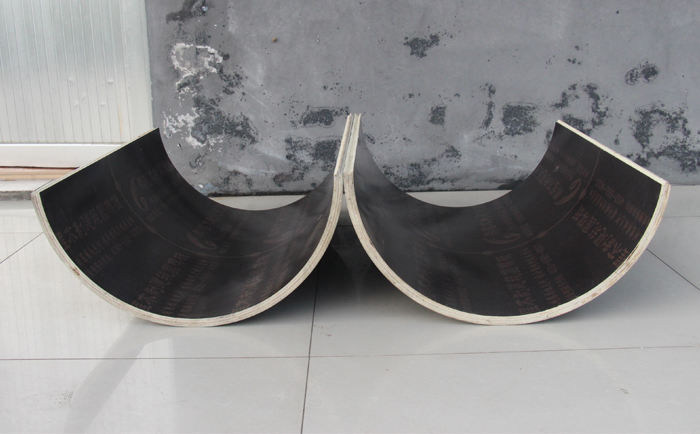

The cylindrical wooden template is made of high-quality poplar core and birch bark as raw materials and is formed by high-temperature pressing.

Diameter:≥200mm can be customized

Diameter:≥200mm can be customized

Process:Single sided high-temperature pressing

Process:Single sided high-temperature pressing

Scope:Various circular building constructions

Scope:Various circular building constructions

Phone/WeChat : +86 150 9292 9372

Cylindrical wood formwork is a new formwork material in the field of construction engineering technology. It uses high-quality birch and poplar as the main material, and uses high-quality phenolic glue as the adhesive, after single-sided hot pressing, double-sided over molding.

Firstly, solve the problem of arbitrary cutting of circular templates

Construction units often encounter overlapping points such as roof beams and columns during the construction process, especially in complex structures such as bridges and temples with many cylinders. The limitations of steel molds and other structures make it difficult to cut them arbitrarily, which often poses great challenges to actual construction.

Pengcheng circular formwork, with its excellent structural performance, can be cut according to the actual size, which greatly reduces the construction difficulty and shortens the construction period for the construction party.

Secondly, solving complex operational problems

When the construction unit uses circular formwork, the installation of steel formwork is bulky and requires the cooperation of a crane or hoist, as well as a lot of manpower to complete. The splicing of strip templates is cumbersome, and the arc error is large, often unable to achieve accurate results.

The Pengcheng round template is lightweight and can be assembled by 2-3 people. Its design is matched with steel strips that are easy to operate and reduce the loss of manpower and material resources.

Thirdly, solve the problem of beam passing

The problems that cannot be solved by the inherent defects of steel formwork, PVC formwork, etc. require the construction party to repeatedly work during the overall overlap, which is very troublesome.

The Pengcheng circle template effectively solves this problem. Its good breathability and insulation not only make the cylindrical surface smooth and flat, but also solve the problem of difficult beam passing by cutting it into any shape suitable for construction with the design of the project.

Fourth: Solve the problem of demolding

In terms of demolding, steel molds are difficult to demold, and generally need to be repaired after 3 uses, which increases a lot of manual labor on the concave and convex surfaces. However, the effect of PVC templates and strip templates after demolding is not ideal.

The Pengcheng round template can be used multiple times up to 6-8 times, and the demolding is simple and easy to operate. The concave convex groove design makes the mortar natural and complete, and the demolding effect is excellent.

Can be cut arbitrarily Wooden circular templates can be cut to any size according to actual requirements.

Can be cut arbitrarily Wooden circular templates can be cut to any size according to actual requirements.  Easy to operate The circular template is lightweight and can be assembled by 2-3 people!

Easy to operate The circular template is lightweight and can be assembled by 2-3 people!  Solving the problem of beam passing Round wooden formwork can have any shape according to the construction of the project.

Solving the problem of beam passing Round wooden formwork can have any shape according to the construction of the project.  Demoulding without plastering Can be used multiple times up to 6-8 times easy to demold and operate.

Demoulding without plastering Can be used multiple times up to 6-8 times easy to demold and operate.