PP plastic film and high-quality birch poplar wood adhesive coating, Used more than 30 times for turnover.

Material:Birch and poplar wood

Material:Birch and poplar wood

Number of uses:Can rotate more than 30 times

Number of uses:Can rotate more than 30 times

Scope:Shear walls high-rise buildings and other engineering projects

Scope:Shear walls high-rise buildings and other engineering projects

Phone/WeChat : +86 150 9292 9372

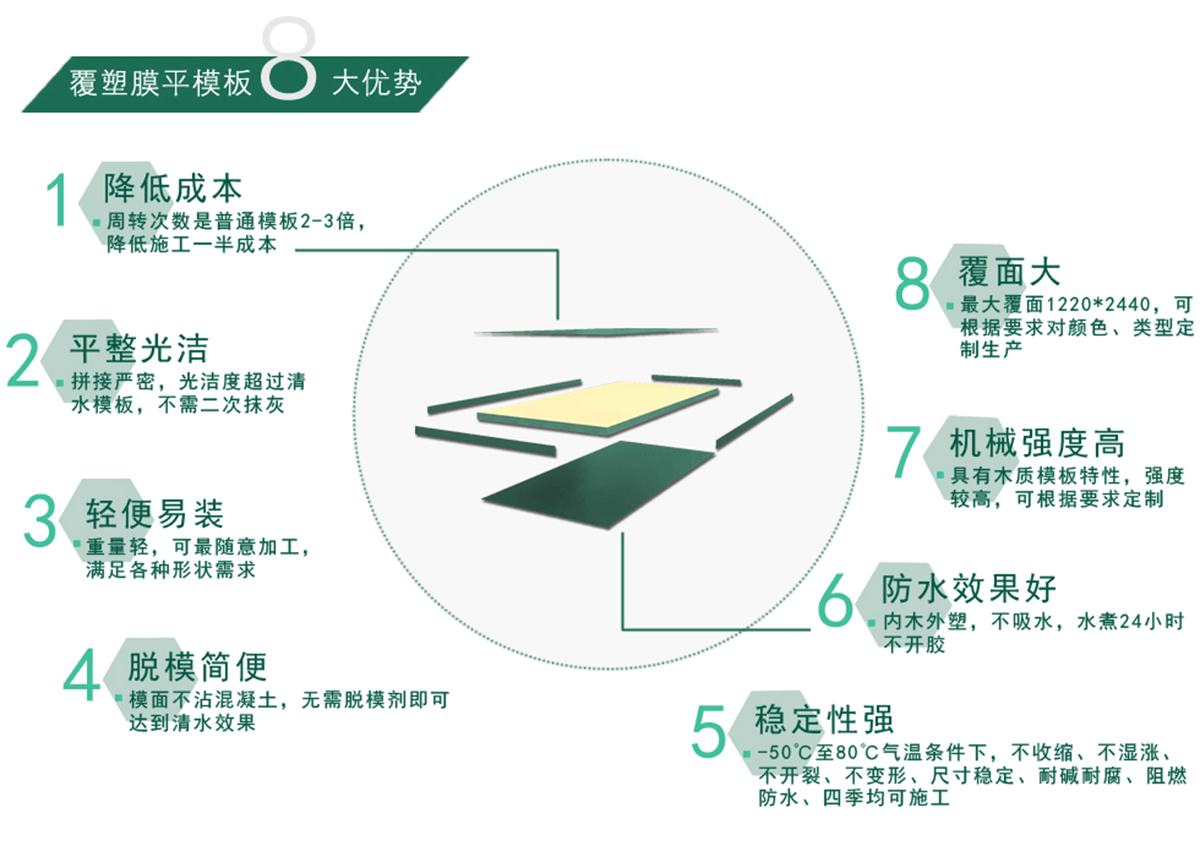

Green and environmentally friendly wooden plastic film (PP) flat template, independently developed by Shandong Fangyuan Building Materials Co., Ltd., has created another generation and upgrade in the field of flat template innovation. Flat plastic film (PP) flat template is made of high-strength, high gloss plastic, non-toxic and environmentally friendly, with a smooth and wear-resistant surface, and no deformation at high temperatures. The clear water effect is particularly outstanding, and the smooth and flat surface has better clear water effect. The large surface PP coated plastic film has better waterproof effect and is widely used in shear walls and high-rise construction. Various sizes can be customized according to customer needs.

Process Explanation

1. The substrate is made by high-temperature lamination of multi-layer triamine adhesive. Boil water for 72 hours without cracking. The pressure elastic strength reaches 5000MPa and the toughness is good. The surface plastic coated sheet is subjected to high-voltage current corona treatment. And combined with specialized imported glue, the sheet does not peel after boiling for 42 hours.

2. It has no deformation, good water resistance, no cracking, and no warping. High turnover times and good demolding effect. It can achieve the effect of a clear water mirror. Its advantages include strong plasticity and the ability to create templates for curved surfaces and arcs. Its nemesis is diesel and harsh oils. Exposure to high temperatures. Long term exposure to wind and rain. No maintenance, no maintenance.

Demoulding, maintenance, and storage

Demoulding: Generally, the principle of dismantling after support, dismantling after support, dismantling non load bearing parts before load bearing parts, and dismantling from top to bottom is followed. A special demolition plan should be formulated before the demolition of major and complex templates. When dismantling the formwork, try not to use too much force or too quickly. It is strictly prohibited to use hammers and pry bars to forcefully smash or pry, as one side of the concrete surface formwork may be damaged.

Maintenance: After disassembling the template, clean it thoroughly and arrange it according to specifications for future use. If long-term storage is required, oil should be applied to its surface, neatly stacked, and covered with a rain cloth.

Storage: After the project is completed, the templates are cleaned and packaged according to specifications and quantities for transportation. Store on a flat and dry site on the construction site, avoiding rain and sun exposure, and avoiding temperature and humidity environments.

Smooth and flat surface The surface of the template is covered with PP plastic film, which is smooth and shiny.

Smooth and flat surface The surface of the template is covered with PP plastic film, which is smooth and shiny.  Multiple turnover times Boiling water for 24 hours and then cooling it down will not reduce its strength, and it can be turned over more than 30 times!

Multiple turnover times Boiling water for 24 hours and then cooling it down will not reduce its strength, and it can be turned over more than 30 times!  High quality hot melt adhesive Does not contain non-woven fabric, it is directly bonded between PP film and core board.

High quality hot melt adhesive Does not contain non-woven fabric, it is directly bonded between PP film and core board.  material Using birch and poplar core boards, Two sided sanding.

material Using birch and poplar core boards, Two sided sanding.